Forestry work is demanding, with extended hours in harsh outdoor conditions and ever-present safety hazards. Sappi Forests (SF) owns and manages 388,000 hectares of land in two regions in South Africa. The plantations are widespread and mostly in rural areas. SF has 860 employees, and its operations are almost 90 percent outsourced to 76 private contractors, who employ almost 10,000 people. Stop and Think Before You Act (STBA) is part of SF's Risk Tolerance Mitigation strategy, aimed at achieving Sappi's safety goal: Twice as safe by 2020. STBA is a four-year initiative to improve safety and eliminate fatalities in SF and its contractor businesses. STBA provides employees with a tool (process) that guides them to safe decisions and behavior. SF has an unfortunate history of fatalities in the workplace. SF contractors' safety performance forms part of Sappi's safety statistics. The company holds them to the same standard as SF employees. Despite initiatives to improve safety, from 2015 to 2016, the number of fatalities increased from zero to six, and safety deteriorated to an unacceptable level. Injuries and fatalities occurred mainly in the contractor operations. The safety performance was unacceptable. In addition to the loss of life, the impact on business included loss of reputation (goodwill and trust) and financial loss (hiring cost of replacements, training costs, material damage, loss in production, investigation costs and investment in preventative activities), which resulted in a strained relationship between Sappi and its contractors. To address the issue, SF appointed two leading international forestry safety experts (Forme Consulting Group and Mets Group) to assess safety management in SF and its contractor businesses. The communication consultancy DevCom did an operational communication assessment to determine the impact of communication on safety. The STBA communication team conducted research among the contractors and engaged employees to unpack safety and communication issues that were flagged in a 2016 employee engagement survey. Primary research included surveys, focus group discussions, in-depth interviews and group discussions, and qualitative data from meetings. The research found safety communication to be poor, affecting safety performance. For safety to improve, SF had to replace its rules-based management culture with a safety culture, as the status quo left little room for creativity and innovation. Diverse demographics, multiple languages spoken in the business and psychographic barriers compounded the problem. Contractors come from diverse ethnic cultures. Illiteracy is high among labor, and employees who are not proficient in English were expected to read lengthy complex safety policies and work procedures, which they then had to communicate to labor. The communication chain from SF to contractor staff was complex and in many contractor businesses the communication between management and shop floor workers was inadequate. This resulted in trust issues---most people said they did not trust each other or the information they received, and they doubted the decisions made. Communication was unclear because management and safety leaders were using confusing language. Communication channels were not suitable for the audiences. The communication tone of voice was angry and perceived as disrespectful. There was a lack of recognition for positive behaviors. Following feedback on the research, SF decided to improve safety by implementing the STBA behavior change model and a complex Hazard Identification Risk Assessment and Risk Tolerance Thinking Tree (HIRAC). SF and its contractors did not have communication staff in their business, and Sappi's regional communications manager was tasked to develop and implement a communication strategy and tactical plan for the implementation of the STBA initiative to change behavior, so that SF could achieve Sappi's safety goal of being twice as safe by 2020.

Forestry work is demanding, with extended hours in harsh outdoor conditions and ever-present safety hazards. Sappi Forests (SF) owns and manages 388,000 hectares of land in two regions in South Africa. The plantations are widespread and mostly in rural areas. SF has 860 employees, and its operations are almost 90 percent outsourced to 76 private contractors, who employ almost 10,000 people. Stop and Think Before You Act (STBA) is part of SF's Risk Tolerance Mitigation strategy, aimed at achieving Sappi's safety goal: Twice as safe by 2020. STBA is a four-year initiative to improve safety and eliminate fatalities in SF and its contractor businesses. STBA provides employees with a tool (process) that guides them to safe decisions and behavior. SF has an unfortunate history of fatalities in the workplace. SF contractors' safety performance forms part of Sappi's safety statistics. The company holds them to the same standard as SF employees. Despite initiatives to improve safety, from 2015 to 2016, the number of fatalities increased from zero to six, and safety deteriorated to an unacceptable level. Injuries and fatalities occurred mainly in the contractor operations. The safety performance was unacceptable. In addition to the loss of life, the impact on business included loss of reputation (goodwill and trust) and financial loss (hiring cost of replacements, training costs, material damage, loss in production, investigation costs and investment in preventative activities), which resulted in a strained relationship between Sappi and its contractors. To address the issue, SF appointed two leading international forestry safety experts (Forme Consulting Group and Mets Group) to assess safety management in SF and its contractor businesses. The communication consultancy DevCom did an operational communication assessment to determine the impact of communication on safety. The STBA communication team conducted research among the contractors and engaged employees to unpack safety and communication issues that were flagged in a 2016 employee engagement survey. Primary research included surveys, focus group discussions, in-depth interviews and group discussions, and qualitative data from meetings. The research found safety communication to be poor, affecting safety performance. For safety to improve, SF had to replace its rules-based management culture with a safety culture, as the status quo left little room for creativity and innovation. Diverse demographics, multiple languages spoken in the business and psychographic barriers compounded the problem. Contractors come from diverse ethnic cultures. Illiteracy is high among labor, and employees who are not proficient in English were expected to read lengthy complex safety policies and work procedures, which they then had to communicate to labor. The communication chain from SF to contractor staff was complex and in many contractor businesses the communication between management and shop floor workers was inadequate. This resulted in trust issues---most people said they did not trust each other or the information they received, and they doubted the decisions made. Communication was unclear because management and safety leaders were using confusing language. Communication channels were not suitable for the audiences. The communication tone of voice was angry and perceived as disrespectful. There was a lack of recognition for positive behaviors. Following feedback on the research, SF decided to improve safety by implementing the STBA behavior change model and a complex Hazard Identification Risk Assessment and Risk Tolerance Thinking Tree (HIRAC). SF and its contractors did not have communication staff in their business, and Sappi's regional communications manager was tasked to develop and implement a communication strategy and tactical plan for the implementation of the STBA initiative to change behavior, so that SF could achieve Sappi's safety goal of being twice as safe by 2020.

The solution

To deliver on the goals and objectives outlined above, we developed a robust communication strategy that united the primary audiences in a common goal, namely that of improving safety. We followed a three-pronged approach.

- First, we engaged the audience in developing a new approach to communication that transcended barriers such as illiteracy, language diversity, culture and gender.

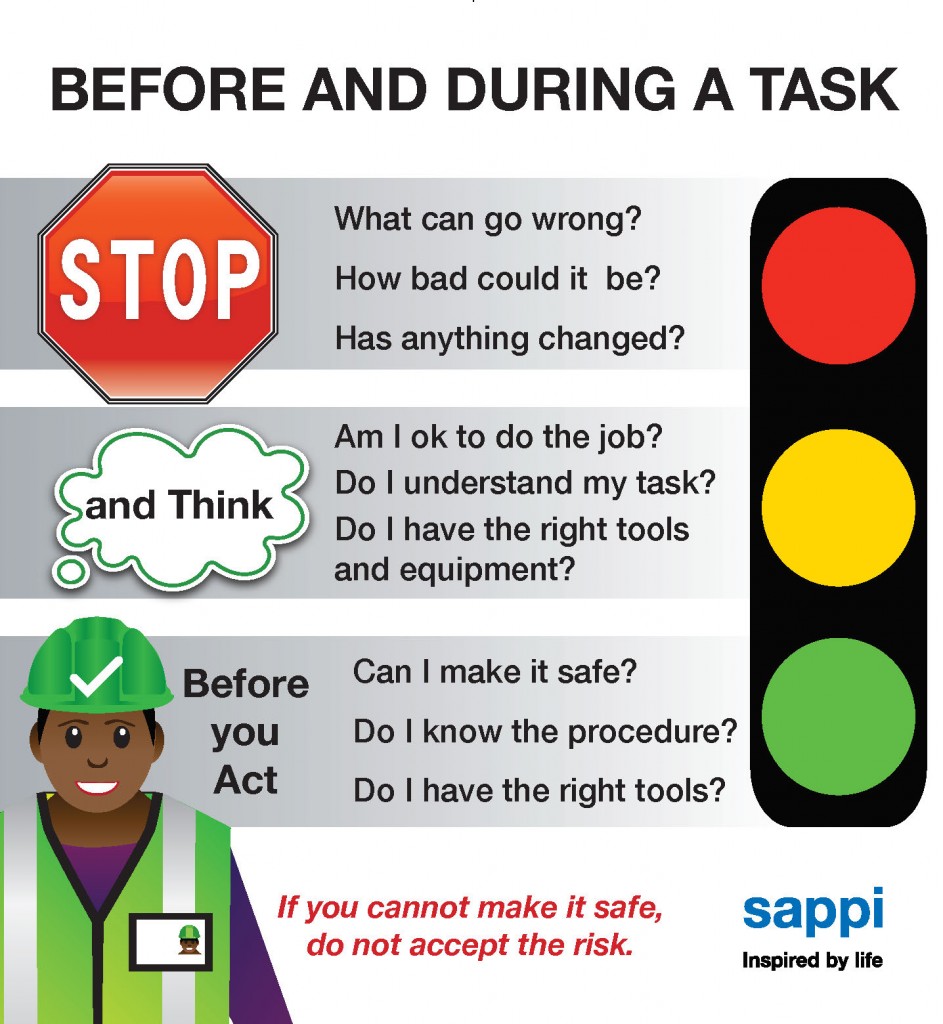

- Second, we empowered them by providing them with a risk mitigation tool to guide them to safe behavior. This tool instructs one to "Stop and Think Before you Act," to ask yourself, If I do this, what could go wrong? If something goes wrong, how bad could it be? What could I do about it?

- Third, we gave them clarity of purpose by assigning roles and responsibilities to each stakeholder group. It was the first step in SF's journey of engaging the minds, hearts and hands of its extended work family to produce a complete change in culture.

Phase 1: Planning, testing and compiling strategy. We consulted the primary audiences and tested various communication approaches, tools and channels on the shop floor and in the boardroom, to determine the most efficient way to engage each audience. We also used this phase to develop and test a diverse range of critical messages, which had to be compelling, speak directly to our goals and objectives and have meaning to stakeholders.

We used specifics to bring the messages to life. For example, we explained what exactly the audience had to think about in "Stop and Think Before You Act."

Phase 2: We segmented the primary audience. To gain audience support, we explained the what, the why and the how. We trained them on communication and facilitation, developed their knowledge, and motivated them to train others. Group 1: The SF operational team's role was that of a STBA coach and supporter. They needed to lead by example in the new way of communicating and practicing STBA. They had to be mindful of their role as supporter, and not the owner of safety and or communication in the contractors' operations, thereby showing trust and restoring relationships. We hosted coaching and alignment workshops for them to help guide them in their new role. In addition to participating in the contractor consultation sessions, they also joined in the Train the Trainer workshops to hone their skills in communication and facilitation, and to learn the STBA process. Group 2: The contract owners needed to "own" STBA and had to take the lead in establishing the new way of communicating. They had to support their safety leaders in implementing STBA and include recognition and affirmation in their approach. They participated in the Train the Trainer workshops with the SF's operational teams and their safety leaders. They received toolkits with all the project material (toolbox talks, posters, fact sheets, etc.) in hard copy and in electronic format so that they could incorporate the STBA symbols in their operational safety material. Group 3: The contractors' safety leaders were the STBA change agents on the shop floor. We followed a process of reflective learning to train them. They also attended the Train the Trainer workshops and were trained in communication, facilitation and the STBA process. They received a certificate of proficiency upon completing the workshop, and the training was recorded as part of their professional development. Group 4: Labor needed to understand and implement STBA. The safety leaders taught them the meaning of STBA and taught them the STBA process through rhyming. They were shown how to apply STBA to their various daily tasks, and in the event of a near-miss incident, they were involved in a team debriefing to discuss the incident. They had fun with STBA at Sappi's Global Safety Week Celebrations.

Engaging the audience through storytelling

Research showed that the audience loved stories, so we adopted a storytelling approach. Visuals made the STBA concepts easier to understand and teach, increased engagement, and improved uptake and recall. Research also showed that symbolism and similes would work well with the audiences. We wrote the STBA process into a story to explain the thinking process, introducing a hero and a villain to juxtapose the STBA process against non-compliance. The audiences named the hero character "Clever Me." They named the villain "Stupid Me"---he was the one who did not stop and think. He was prone to be injured or killed on the job and his family suffered the consequences. The story engages the audience on how we all have the power to choose our destiny. We were concerned about using the word stupid to describe a person, as we felt it was disrespectful. Research showed us that we were mainly wrong, as only about half of one small sub-group team objected to the name. Their material was adopted to reflect the name they gave the villain ("Irresponsible Me").

We introduced a generic symbol to represent hazard throughout the business. Labor considered many symbols but chose the black mamba. The mamba proved to be a compelling image that always elicited a dramatic response from audiences. The use of a standard set of symbols throughout all safety communication created a universal, consistent language. We catered to color-blind stakeholders by using symbols on the characters' hard hats. People learned the meaning of each symbol and could immediately identify the characters and associate them with correct and incorrect behavior. Contractors and SF incorporated STBA symbols in their operational safety communication. We translated complex processes such as the HIRAC Thinking Tree and SF's written work processes into picture stories. Highly visible STBA symbols served as triggers for people to apply STBA throughout their workday. The audience connected exceptionally well with the material and understood and accepted that behavior is your own choice. Research indicated that some also implemented STBA at home. We use the symbols and characters as a generic approach to developing all STBA material and older existing material is being reworked to include them. Key messages:

- Hazards can injure or kill you. They are like snakes. They are always there and if you don't look for them, you will not see them.

- Stop and Think Before you Act.

- Think about the hazard. What can go wrong? How bad can it be? What can I do about this?

- Make it safe or walk away from the hazard.

- My behavior is my choice and I choose to be Clever Me.

- We will be twice as safe by 2020.

- We will improve communication by keeping it simple and to the point.

- We will improve relationships by consulting and collaborating with our stakeholders.

The results

Objective: Reduce fatalities to zero by 2020, reduce Accident Injury Frequency Rate (AIFR) by 2.5%, reduce Lost Time Injury Frequency Rate (LTIFR) by 4%, reduce Lost Time Injury Severity Rate (LTISR) by 62% and reduce Injury Index (II) by 62.41%.

Result: Targets exceeded. Fatalities were reduced by 83% in year one. The Accident Injury Frequency Rate (AIFR) was reduced by 3.67%. Lost Time Injury Frequency Rate (LTIFR) reduced by 8%. Lost Time Injury Severity Rate (LTISR) reduced by 64% and the Injury Index (II) reduced by 67.49% by 30 September 2017.

Output objective: Increase knowledge of STBA by training one safety leader in all 76 contractor companies on STBA and motivate them to train 5,000 labor (almost 50%) to lower risk tolerance, to improve safety by 30 September 2017

Result: 486 contractor employees representing all 76 contractor companies were trained in Train the Trainer sessions on communication and facilitation skills. They trained almost 10,000 people in STBA (almost 100%). Qualitative reviewing in class of their knowledge and ability to present to others showed a high adoption and capability, and their knowledge of STA increased.

Outtake objective: Improve relationships with contractors and their labor through consultation, to achieve support for the STBA initiative, thereby increasing stakeholder engagement with the behavioral change process, resulting in improved safety by 30 September 2017.

Result: We conducted 41 consultation sessions engaging 576 contractors and their labor and involved 80 SF's operational employees. Research indicates an improvement in relationships as well as safety. This is the first safety initiative Sappi has implemented in years that 100% of contractors actively participated in and which operational budget is paid for.

Outtake objective: Increase understanding of STBA by improving and simplifying safety communication, messages and material, resulting in more people understanding and applying the STBA process to reduce at-risk behavior by 30 September 2017.

Result: A new approach to communication, including audience-specific STBA material was implemented and almost 100% of the audiences (just under 11,000 people) were trained to apply the STBA behavior process. Research shows a high adoption of STBA, which reduced risky behavior, as indicated by the safety statistics.

Goal: Improve communication in SF and convince employees that communication is important.

Result: Research indicates that communication in SF improved from 60% in January, to 86% in June. 100% of contractors said that communication improved through Sappi's efforts, and 87% of contractor businesses benefited from it.

Goal: Implement STBA as a behavior-change tool in SF contractor operations, to help achieve SF's Twice as safe by 2020 safety goal.

Result: Research indicated that behavior has changed. SF achieved its safety target, indicating that the company also improved reputation and curbed financial losses. Communication and relationships have also improved. The company and its stakeholders are well on their way to achieving their "Twice as Safe by 2020" goal. Leander Jarvel, forestry general manager for the KZN area, had this to say:

"In my 14 years of operational management, I have never seen an initiative take traction with the contract owners, managers and their staff like STBA. At all levels, there is enthusiasm for the simplicity of the message. It is so rewarding to hear contractors talk about their operators and supervisors in their business identifying and mitigating risks in their operations. No short cuts. Practicing what is preached."

This campaign won a 2018 IABC Gold Quill Award of Excellence in the Safety Communication category and a 2018 Gold Quill Award Best of the Best Award. For more than 40 years, IABC's Gold Quill Awards program has evaluated the work of communication professionals around the globe, recognizing the best of the best in the profession.